上一张

下一张

Email:

jschaori@outlook.com

Email:

jschaori@outlook.com

Whatsapp:

19714819527

Whatsapp:

19714819527

Activated carbon fiber organic waste gas purifier for in vitro regeneration carbon fiber organic waste gas purifier (organic waste gas treatment device). Using carbon fiber as adsorption material, its adsorption capacity is 20 to 40 times higher than activated carbon, purification efficiency is 95 to 99%, the equipment has a small footprint, easy to maintain, less ancillary equipment, wide range of applications, high, low concentration of odor, waste gas has a better odor removal effect. Low operating cost, simple operation and easy maintenance. No secondary pollution, low energy consumption, small load on the surrounding environment. Is the international operation for many years and has been successful method, is a relatively mature process.

Treatment gases: acetone, butanone, butanol, methanol, formaldehyde, benzene, toluene, xylene, styrene, methyl tert-butyl ether, ethyl acetate, methylethylene chloride, ethane, pentane, natural gas, automobile exhaust, hydrogen sulfide, hydrogen disulfide, mercaptan, ammonia and various organic waste gases.

Application fields: chemical production, paint industry, steel manufacturing, paint factory, paint workshop, fume workshop, catering industry, furniture production, landfill, paper factory, adhesive production, printing industry, gasoline production, petrochemical and chemical industry.

(1) Adsorption performance

Activated carbon fiber felt is a new type of efficient adsorption material, which has high adsorption effect on harmful gases and fast adsorption and desorption speed. Carbon fiber felt should be desorbed with hot air (105 ° C) and can be recycled. It has the corrosion resistance of not afraid of carbon alkali, and can prevent organic waste gas containing benzene series, sulfur dioxide, carbon monoxide, nitrogen oxides, hydrogen sulfide, petroleum gas, odor, etc. All have obvious purification effect.

| name | index |

| Filament diameter(um) | 8-9 |

| Specific area(m²/g) | 1000-1500 |

| Filter layer(g/m²) | 33-330 |

| Bulk density(g/cm³) | 1-10 |

| Benzene adsorption capacity(%) | 30-52 |

Regeneration method

After saturation, the carbon fiber felt filter cartridge is taken out and put into the container, heated by steam for 10-15 minutes to take out and dry, and then loaded into the equipment for continued use. The steam gas is condensed through the condenser, and the organic solution is separated from the storage liquid separation bucket. If the separated material is not useful, it can be poured into the coal pile to burn.

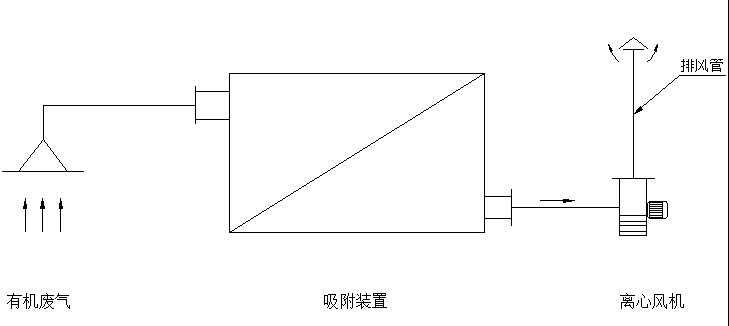

Structure purifier is composed of air inlet, filter, adsorption section, air outlet and so on.

After the organic waste gas enters the box from the inlet, it is filtered by the filter first, and then enters the adsorption section, which is absorbed and purified by the adsorption section. The purified air is discharged into the atmosphere by the fan, the saturated carbon fiber is taken out and regenerated, and the regenerated filter cartridge can still be used after being installed.

This product is used for the purification of benzene-containing substances in the spray painting process. The purification efficiency of the paint is 91-99%, and the concentration of benzene in the air after purification is 0.068mg/Nm³. Toluene concentration was 7.48mg/Nm³. Symbol National and local emission standards.

This product has a total of ten models, processing air volume of 2000-24000m³/h, its purification efficiency of more than 95%, the company can also make non-standard products according to customer needs.

Related Products

Related Products

Under the action of the catalyst, the active ingredient of the catalyst can convert the organic matt...

Learn More

The exhaust gas is powered by the fan, and the negative pressure enters the activated carbon adsorpt...

Learn More

RTO (Regenerative Thermal Oxidizer, referred to as RTO), regenerative thermal oxidizer, is a kind of...

Learn More

Activated carbon fiber organic waste gas purifier for in vitro regeneration carbon fiber organic was...

Learn More